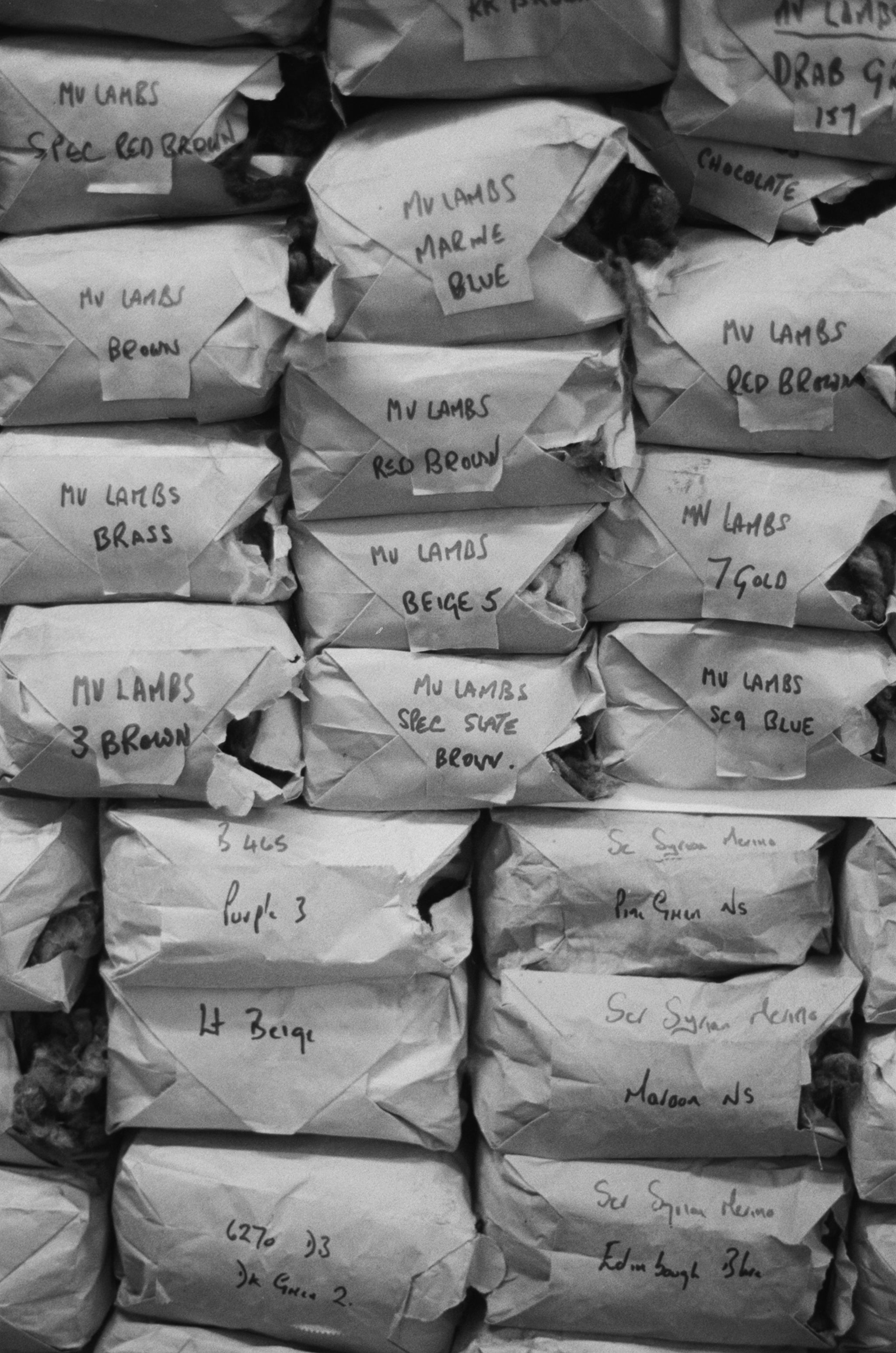

The British fabrics within our house Tessuti collection are spun, woven and finished within a 6 mile radius in Huddersfield. Each part of this process has a distinct impact on the final cloth and is vital to achieving our aesthetic.

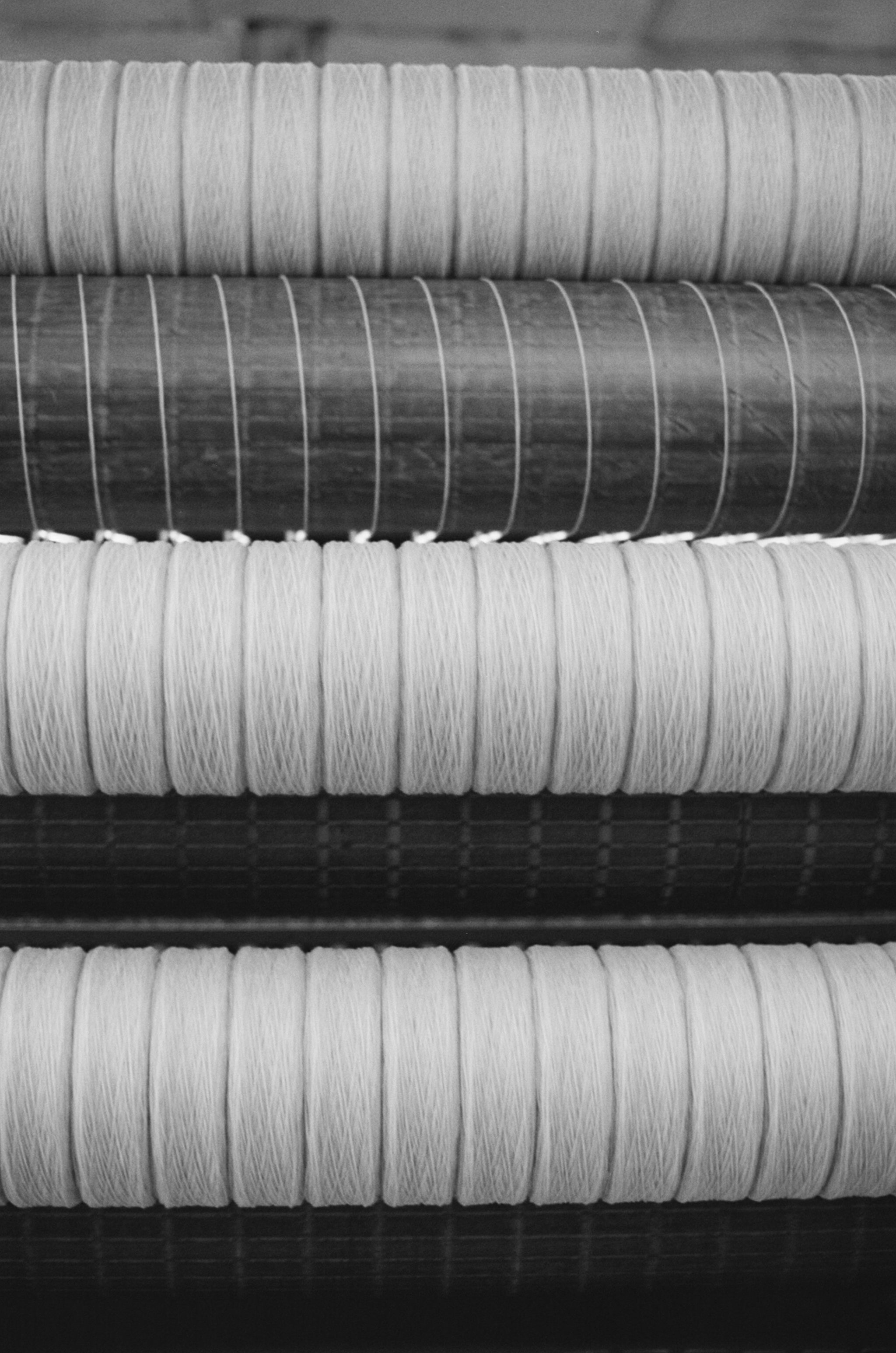

If one were to compare designing cloth to painting, then the spinning of the yarn is the mixing of the paint, the weaving the painting itself and the finishing setting the work into place. Spinners and finishers are often an underappreciated part of the process, with weaving mills with brand names receiving consumer attention and adulation. Yet their expertise has a huge impact on the final product; it's the spinners that give high-twist wool yarns their strength and tension, and finishers who can take the sheen and press off a cloth whilst adding texture.

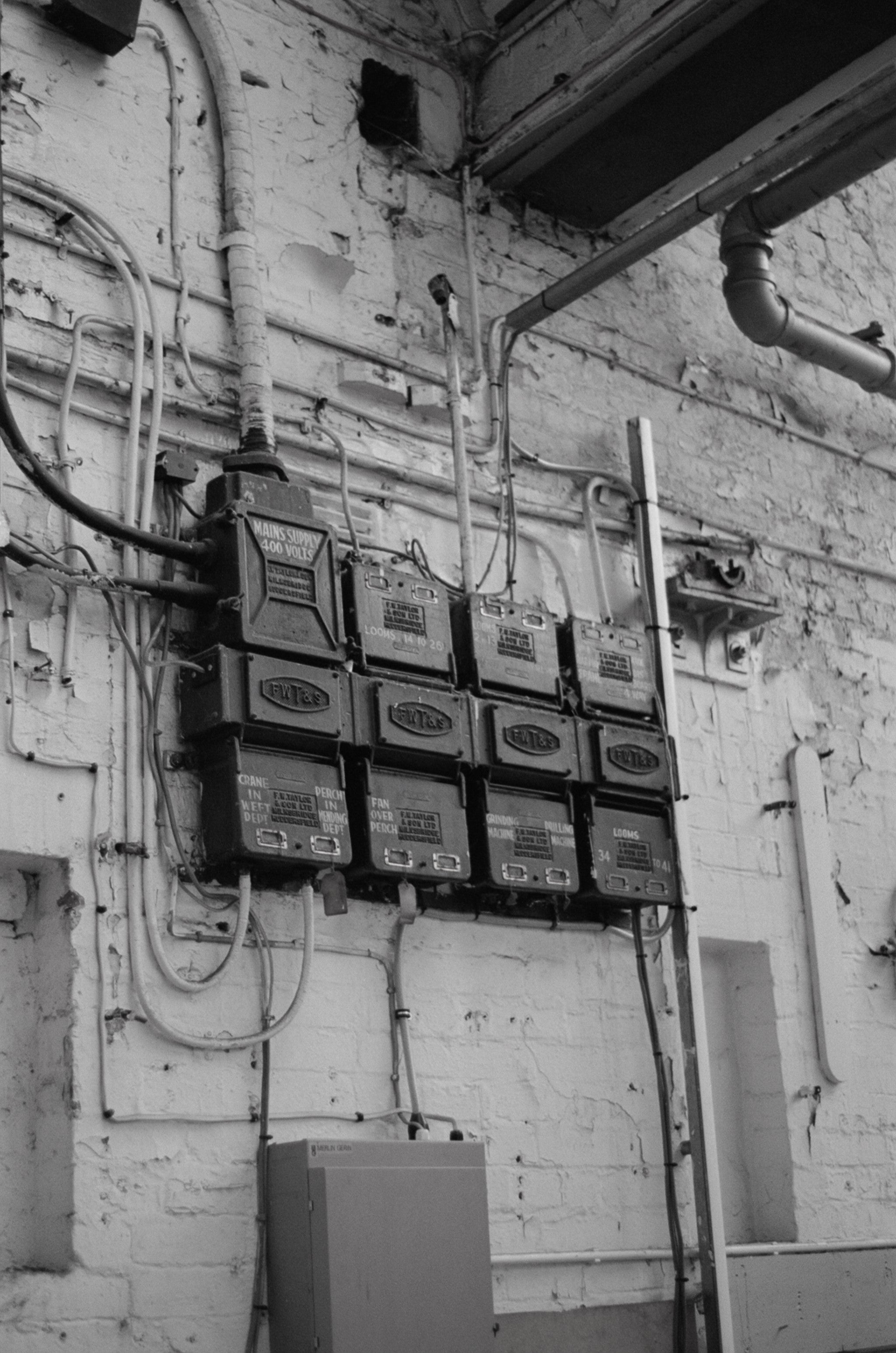

In some regards designing and making fabric in the UK is a bittersweet experience. The industrial buildings that lie on the valley floors where wool manufacturing was once rife are more likely to be flats than mills today, whilst the output of British wool spinning has changed rapidly from 80% clothing to 80% knitwear in the last few decades.

Yet the small portion that is left is exceptional, a network of Victorian buildings with machinery from the 19th century to the present day sitting side by side. Instead of the vertically integrated fabric behemoths that one can still find in Italy — where spinning, weaving and finishing are done under the same banner — Huddersfield is instead home to a host of independent businesses working hand in hand across the different stages to produce cloth that is reflective of their environment.

We're grateful to our small place in this ecosystem and the area's expertise, utilizing it and coaxing it towards our point of view so we can do our best to design the matte, textured and interesting cloth we've become known for. Whilst the team checked up on AW25 developments, we brought along our cameras to capture a flavour of a working day at a spinner, weaver and finisher.

-- Jake Grantham